Search

ICNAP is a collaborative center where we come together to address and solve the challenges of digitalization

66

Projects

15

Services

49

Files

7

Topic Fields

70

Scientific Contributors

4

Institutes

To fully leverage the benefits of our resources, we invite you to become a member of our community. Membership provides you with exclusive access to all project results, allowing you to delve deeper into the world of ICNAP.

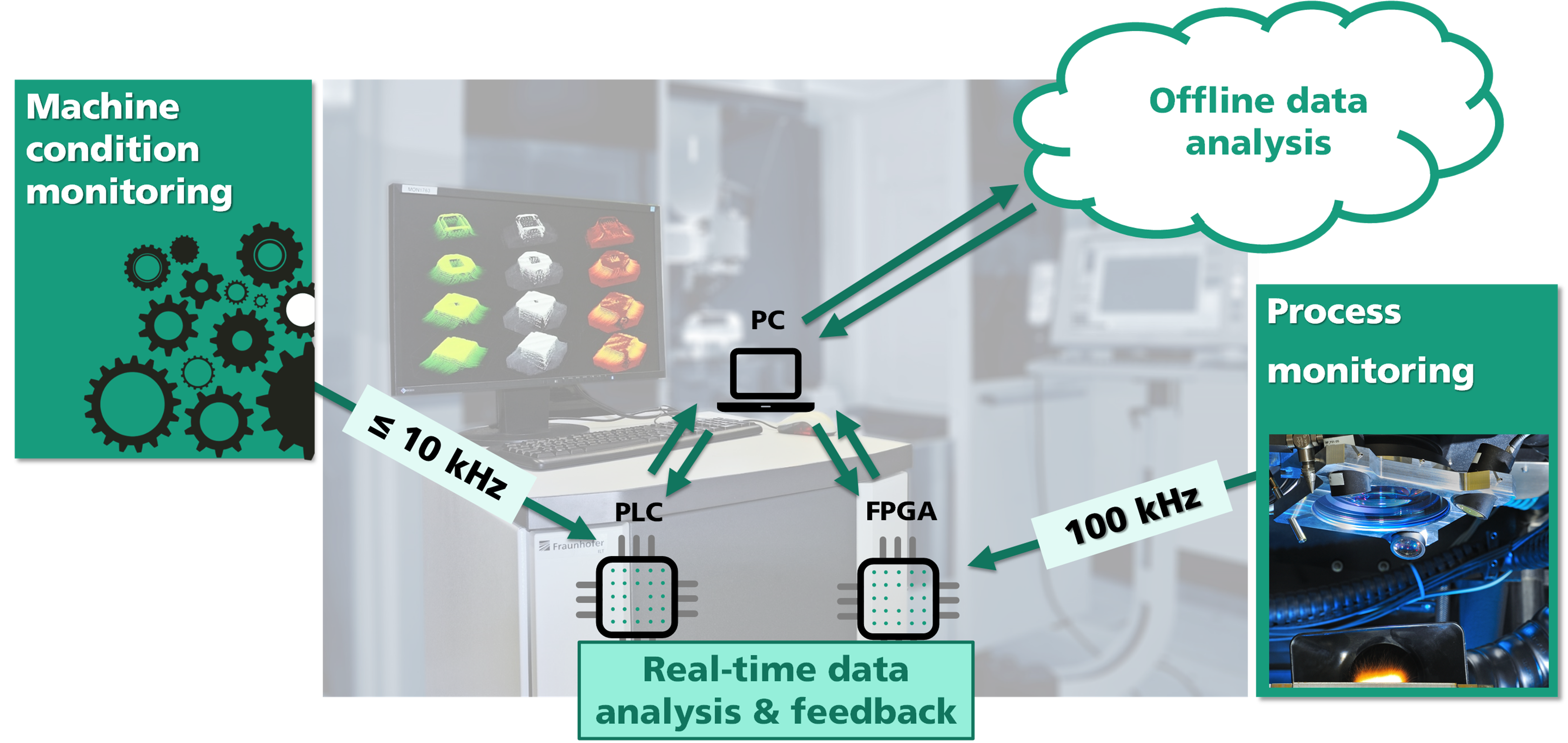

The project aimed to enhance a machine's capability to monitor its system changes, automatically register new components, and adapt to sensor feedback using previously gathered offline data. The existing data acquisition system was upgraded to record sensor data and user-provided information. An analysis method for defect detection was also developed to run alongside the machine's operations. All collected data were assessed to determine their storage needs based on volume and relevance to the use case.

| Topic Fields | |

| Published | 2021 |

| Involved Institutes | |

| Project Type | ICNAP Research/Transfer Project |

| Responsibles |

Contact us to get in touch! With a membership, you’ll gain full access to all project information and updates.

The goal of this project was the identification of the requirements on the machine to track and store the changes inside the machining system, and automatically communicate the usage of new machine components, sensors, or processing parameters. The previously developed data acquisition system was therefore extended to detect and save the details about the connected sensors, as well as further information through the user input. In addition, the machine is to be made able to improve its reaction to sensor signals based on the knowledge gained offline. For the preparation, an extensible analysis for defect detection was developed and is executed parallelly to the machining. To support the future offline analyses, the entirety of the collected information was evaluated to decide about their mid and long term storing depending on the amount of data and their significance for this specific use case.

© Fraunhofer 2025